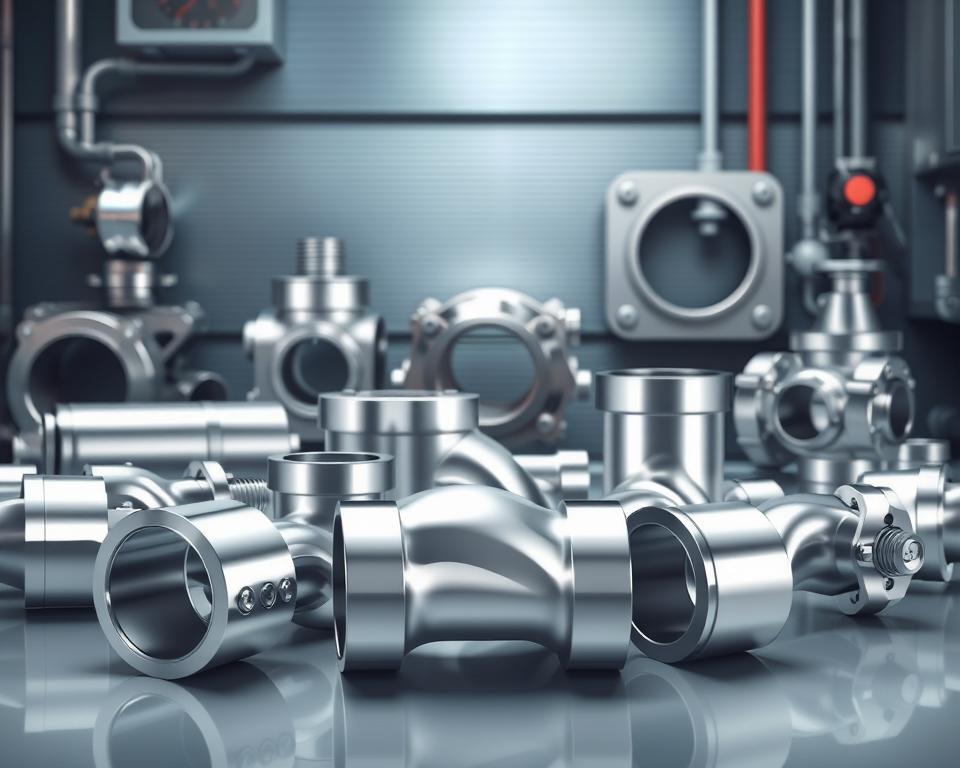

Advanced Tri-Clamp-Style Sanitary Fittings for Strict Sanitation

Whenever cleanliness saves lives, even microscopic gaps count. Therefore, companies like Installation Parts Supply offer precision-engineered solutions minimizing contamination. Their hygienic connection systems combine endurance with tool-less construction, rendering them a top choice for facilities that demand perfection.

These fittings do more than preventing leaks – they’re intended to surpass the exacting criteria of food manufacture, drink-line facilities, and biopharma plants. Manufactured using chemical-resistant stainless, they tolerate ongoing sanitizations while keeping rigidity. The build mindset parallels industry leaders like Alfa Laval, focusing on Tri clamps fittings smooth surfaces and quick disassembly.

How do these connectors stand out? Think one-grip assembly and tool-free maintenance. Technicians welcome the intuitive design during demanding cycles, while plant managers prize standardized performance across pipelines. Every piece faces rigorous inspections to meet FDA and 3-A Sanitary Standards.

Primary Highlights

- Preferred by technicians for leak-proof performance in sensitive settings

- Constructed with food-grade stainless steel for long-term resilience

- Simplifies compliance with food safety and pharmaceutical guidelines

- Cuts stoppage through no-tool fitting and sanitation

- Strengthened with QC procedures equalling global benchmarks

Product Snapshot & Benefits

Secure couplings are the backbone of sterile workflows. Installation Parts Supply designs components that marry precision engineering with real-world usability. Their systems provide hermetic sealing while easing cleaning cycles—critical for industries where speed and safety intersect.

Elite Grade & Hygiene Compliance

Every unit faces intensive trials to comply with worldwide norms. The metals fight rust and pockmarks, even after continual wash-downs. Fluid-tight rings banish contamination, a feature hailed by dairy processors and pharmaceutical manufacturers alike.

These couplings reflect the standards of leaders like Alfa Laval, supplying smooth surfaces and uniform dimensions. Versatile options integrate with legacy piping, cutting upgrade expenses. Crew report 30% faster assembly compared to traditional threaded systems.

Competitive Advantages from Installation Parts Supply

Tailor-made production separates IPS from competitors. Looking for unusual geometry or rare plating? Their team co-designs with users to deliver custom parts. Quick shipment and 24/7 technical support sustain throughput.

The advantages surpass mere longevity. Quick-release separation shortens stops during cleanliness checks. Bottling facilities using these connectors record fewer production stoppages and balanced streams. It’s not just about satisfying codes—it’s about going beyond without strain.

Engineering Specs & Construction Details

High-accuracy design meets flexibility in modern industrial systems. Installation Parts Supply crafts components that harmonize tight specs with versatile designs. Their philosophy ensures trouble-free merging into running equipment while retaining exacting sanitary guidelines.

Selectable Materials & Polishings

Every project has unique needs. That’s why options span 304 through 316L stainless, picked for strength and corrosion resistance. Surface treatments like electro-shining yield mirror-like smoothness, cutting microbial stickiness by up to 40% compared to standard finishes.

| Finish Type | Key Feature | Compliance |

|---|---|---|

| Electropolished | Ultra-smooth surface | ASME 3A, ISO 9001 |

| Mechanically Polished | Cost-effective shine | 3-A Sanitary Standards |

| Bead-Blasted | Non-reflective texture | FDA Food Code |

Manufacturing processes utilize optical scanners to confirm uniform wall thickness. Narrow allowances (±0.005″) prevent weak spots in high-pressure environments. During quality checks, components experience X-ray scans and pressure tests to uncover microscopic flaws.

Tailoring surpasses looks. Clients request specific angles, flange sizes, or specialized coatings for chemical resistance. These personalized selections help industries keep pace with changing codes without tearing out full lines.

Application & Install Guide for Tri-Clamp Sanitary Connectors

Today’s accelerated sites expect hardware that fit fast yet perform reliably. These clamp assemblies excel in environments where pace dovetails with cleanliness. Their design does away with heavy tooling, empowering teams to prioritize production rather than setup struggles.

Hassle-Free Fitting Method

Coupled flange rims and a centered gasket create error-proof locks in seconds. Operators fit the parts, seat the squeeze band, and secure manually – no wrenches required. This approach lowers setup slips while holding steady load across the joint.

| Step | Traditional Method | Modern Solution |

|---|---|---|

| Alignment | Thread matching required | Flanged ends self-center |

| Sealing | Multiple tape layers | Single food-grade gasket |

| Securing | Torque wrench needed | Hand-tightened mechanism |

Adaptable Links Between Systems

Between polished pipes and reactors, these interfaces unite different pieces smoothly. The uniform design fits into various diameters, allowing quick reconfigurations during product changeovers. Dairy plants frequently rely on them to flip between cleaning cycles and production runs smoothly.

Upkeep units enjoy how components separate for thorough sanitation. Smooth surfaces halt grime collection, while the absence of threads eliminates hidden contamination risks. Weekly cleanings need half the hours compared to older connection methods.

Field Deployments and Rule Conformity

Across nano-brew houses to biotech sites, modern facilities lean on connectors that match assorted tasks while conforming to tight guidelines. Installation Parts Supply brings solutions used across sensitive industries where product purity can’t be negotiable. Their designs tie output to standards, forging setups that work under strain.

Food, Beverage, and Pharmaceutical Sectors

Inside culinary process sites, quick-change connections reduce effort when toggling production and sanitation. Breweries rely on custom tees to manage complex flow paths while eliminating cross-mix hazards. Pharmaceutical manufacturers count on sealed couplings to shield active agents during sterile transfers.

These parts are available in varied dimensions to match piping layouts, from small-scale laboratories to mega fermenters. Dairy processors value how standardized parts reduce downtime during equipment upgrades. Even tiny alterations in production processes are managed through modular designs.

Alignment to Global Codes

Every item hits or surpasses benchmarks set by global organizations. ASME-certified materials tolerate pasteurization in pasteurization systems, while ISO-compliant finishes deny biofilm. The 3-A symbol confirms appropriateness for direct contact with consumables.

Tri-Clamp unions demonstrate the devotion. Their uniform dimensions supply hermetic closure across automated lines. Third-party audits verify traceability from raw materials to finished goods, offering QA departments assurance.

By matching these guidelines, facilities ease compliance tasks and get sign-offs swiftly. It’s not just about sidestepping fees—it’s about securing customer faith through transparent sanitation.

Final Insights and Next Steps for Your Sanitary Solutions

Selecting parts that pair output and rules shapes operational success. Installation Parts Supply brings systems blending strength and sanitation, guaranteeing leak-free performance across food, pharma, and beverage environments. Their products surpass rigorous standards while streamlining routine tasks through intuitive assembly.

With options spanning stainless steel grades and custom finishes, solutions match individual line needs. Whether moving scalding media or endless sanitation loops, material choices and surface treatments maximize durability. Professionals value the vast catalogue of joints made for particular throughput and pressure.

Ordering proves straightforward, with pro advice waiting to suit project goals. Express delivery and minimized wait times shrink line interruptions during upgrades or replacements. Periodic cleaning becomes effortless thanks to tool-free disassembly and slick interiors that fight fouling.

Eager to upgrade production assurance? Speak with Installation Parts Supply to investigate bespoke options – from tri-clamp-style to tri-clamp variants – reinforced by premium QC. Their team secures code compliance today while positioning you for upcoming needs.